With the popularity of cell phones, more and more people are starting to own the first iPhone or even the second. When the cell phone is used for a long time, it will always fall more or less from the hand to the ground, and the iPhone screen will fall if it fails several times. In order to buy a iPhone, many people spend several months of salary. Considering that the cost of re-buying a iPhone is very high, everyone will want to change the iPhone screen instead of changing the entire iPhone. However, there are not many people who usually touch cell phone screens. It is not easy for ordinary people to distinguish between good screens and bad screens, how to select a good mobile phone LCD screen? Today Ander LCD Factory will be popularized for everyone.

The main factors affecting the quality of cell phone screens are the raw materials of cell phone screens, the quality of cell phone screens made by raw materials of different suppliers and different costs are definitely different; the production environment of cell phone screens, the production temperature of dust-free workshops, humidity, anti-static The treatment of the measures will affect the quality of the cell phone screen; the quality check of the cell phone screen, the brightness test, the white balance test, the waterproof test, etc., and the finished product test of the quality inspection department is also very important, and some defective products will affect the quality of the whole batch of goods; The packaging of the cell phone screen, the cell phone screen is relatively fragile, and it is more afraid of collision. If it is not packaged, it will affect the service life of the cell phone screen, etc.

Today Ander LCD Factory wants to tell you about the impact of production processes on cell phone screens. Before introducing the production process, we will first give you several industry terms: GFF, GG, OGS, Incell, Oncell.

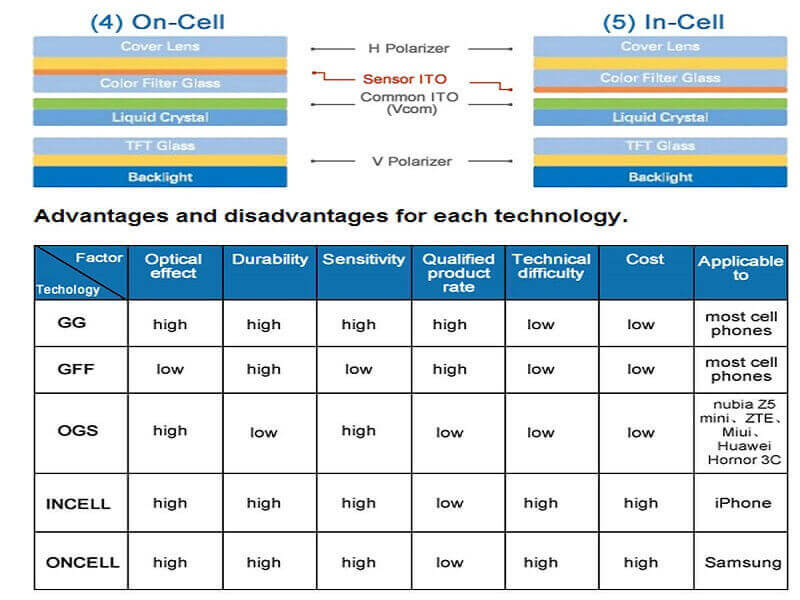

G+G (glass lens+ glass sensor): Only one glass sensor, ITO glass in rhombus structure to support touch in multiple points.

G+F+F (cover glass+ film sensor+ film sensor): Two layers film sensors, ITO glass in rhombus structure to support touching in multiple points.

OGS (one glass solution): Laminate touch screen and glass into one piece. The glass is plated with ITO conductive layer and people directly make coating and photo etch on the glass. This LCD screen will be thinner and cheaper.

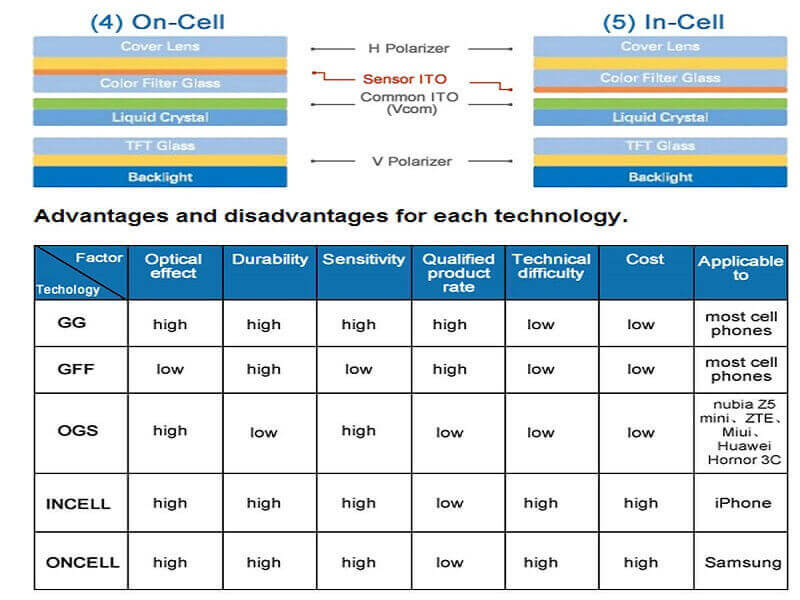

In-Cell: Touch panel with sensor ITO under color filter glass.

On-Cell: Touch panel with sensor ITO between polarizer and color filter glass. This technology is much easier than in-cell technology.

G+G is currently the most widely used cell phone technology, and the screen stability is also better; G+F is the technology that Apple officially announces to be promoted in the future, and the future development trend is relatively good. Currently Ander LCD Factory is vigorously developing this technology;

OGS uses only a simple layer of film, which can cause safety problems, and is not currently widely used;

Incell and Oncell are still new development technologies, the cost is still relatively high, and the stability of the cell phone screen is not very good. There is still a long time before the technology matures.

I hope this article can let you know several factors that affect the cell phone screen. In the next article, we will introduce more professional knowledge about cell phone screens. I hope everyone will pay attention to our website www.Ander-Parts.com to get the latest cell phone screen and cell phone accessories, see you soon.